Warehouse operators can make the right connectivity choice between Wi-Fi 6 and 5G based on size, scale, and availability.

The changing dynamics of a warehouse are driving changes in the technology needs of the warehouse – inside and outside.

As per Ericsson’s article in 2019, there were 4,000 robotic warehouses in operation worldwide. And latest research predicts four million commercial robots to be at work in 50,000 warehouses across the globe by 2025. That’s a 12-fold increase in the span of just six years.

This data points to the need for strong connectivity within the warehouse, and this brings us to the biggest debate of all –

Is Wi-Fi 6 or 5G needed?

Why connectivity matters in a warehouse

The big advantages of better connectivity in a warehouse are

Reduced labor costs

Reduced labor cost can be achieved by automating warehouse operations all the way from usage of AGV, ASRS to any other mechanism and effectively controlling them using a better-connected warehouse.

Improved productivity

A good interconnected warehouse improves the productivity of the warehouse from 15-30% easily as speed of operations improves drastically, and fault reduction and tolerance is brought down to bare minimum.

Continuous tracking

Every object inside a warehouse can be tracked for its location, rack and row, thereby ensuring better visibility. Continuous tracking and tracing is the best way to speed up the picking, order processing and order filling processes.

Enhanced communication

Communication among operators, workers and managers can be effectively managed and enhanced with Augmented Reality/Virtual Reality, and dashboards that provide real-time accurate information. This allows warehouse operators to do the right things at the right time.

Route optimization

When a warehouse is interconnected, route improvement and pickup optimization can be achieved with extreme accuracy. From the arrival of a truck at the receiving dock, to the departure of the truck from the shipping dock, every spot will be optimized.

Wi-Fi 6 vs 5G: The big debate

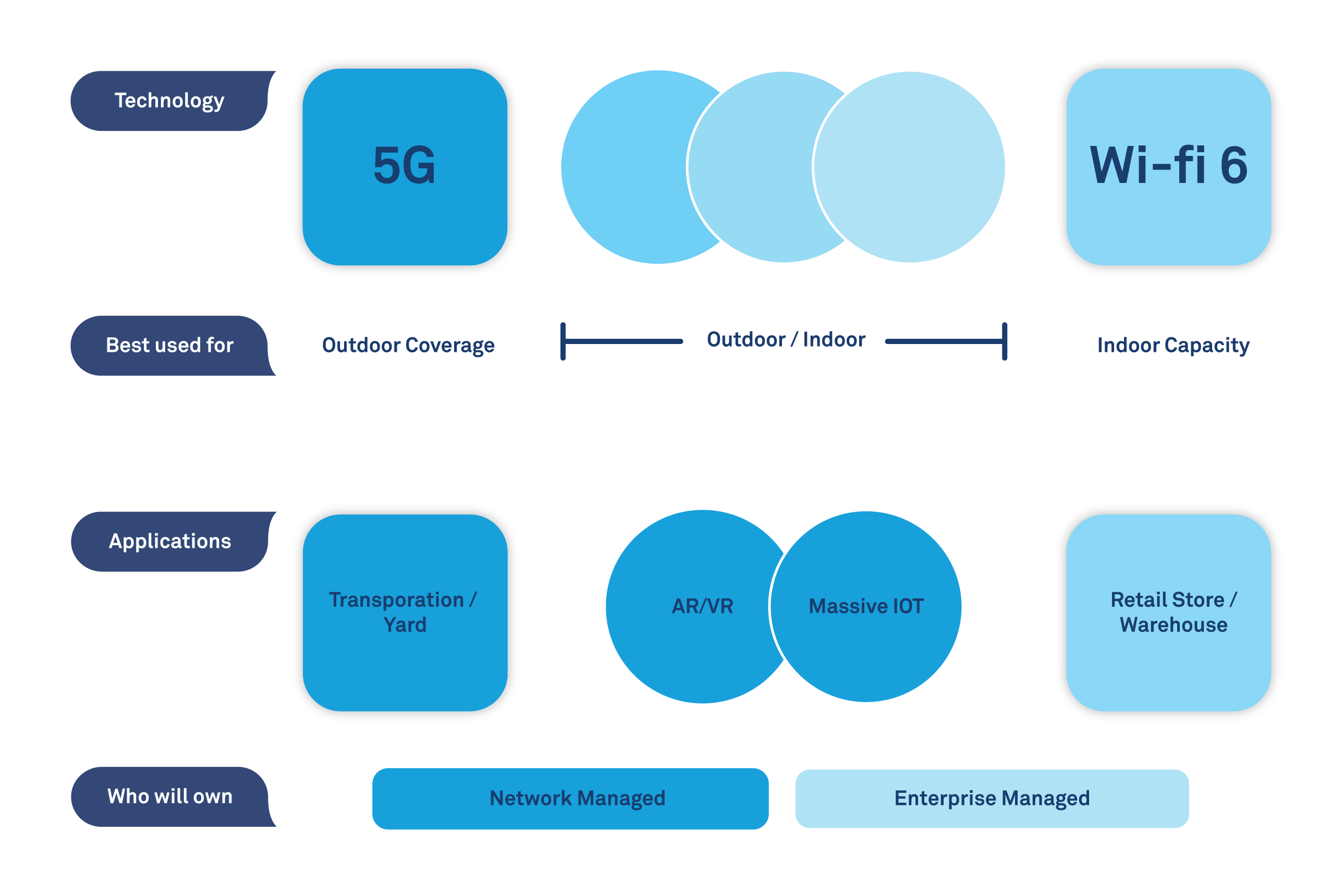

Both 5G and Wi-Fi 6 offer high reliability, low latency and quality of experience, but they are for different use cases. Figure 1 gives an indication of the areas where 5G and Wi-Fi 6 will play critical roles. A warehouse is all of these areas put together and it has a massive IoT need with so many devices to be connected. The size of a warehouse can vary from few hundred meters to kilometers based on the size and scale. We all know 5G will operate from 30 GHz to 300 GHz, so what is then the hindrance to bringing 5G into a warehouse?

Figure 1: 5G vs Wi-Fi 6

The private network challenge

The major challenge where Wi-Fi 6 will win over 5G is the availability of a private network. This will become a big problem as network providers will not be able to give licensed bandwidth for operation. However, 5G will provide the support for large outdoor usages as well as provide the SIM based security, which will enable better coverage to take care of the yards of a warehouse.

So if the network providers are able to provide a spectrum that will be a big push towards 5G usage in warehouse. 5G probably can also win the cost game with the number of nodes a Wi-Fi 6 needs to take care of the millions of devices that are inside a warehouse. But the key would always be the spectrum availability.

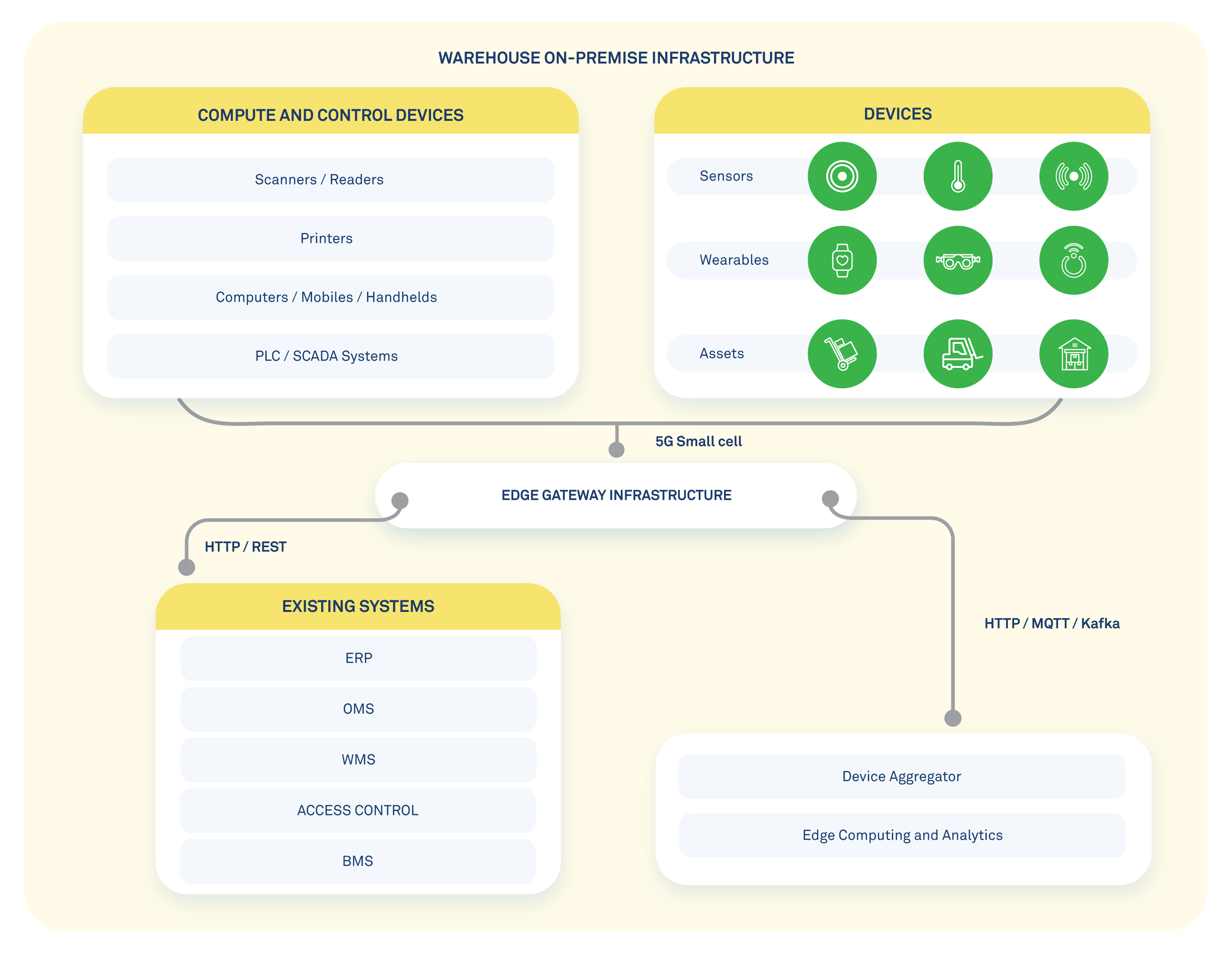

Figure 2: Inside the warehouse connectivity

Figure 2 describes the best of what happens inside the warehouse. When the connectivity is only restricted to within a warehouse and indoors, then 5G probably would be an overkill.

The connectivity choice

There are many pros and cons related to both, Wi-Fi 6 and 5G, when it comes to warehouse connectivity, but the choosing criteria would be and should be based on three critical factors.

- The size of the warehouse – Bigger the size, better to go for 5G

- The connectivity requirement – Only inside the warehouse, do it with Wi-Fi 6

- The private network availability – Without a licensed spectrum, there is no choice but Wi-Fi 6

The connectivity debate can go on, nevertheless, the warehouse operators must make sure they chose the right technology based on size, scale and availability.

By Venkat Jayaraman – Distinguished Member of Technical Staff and Head of Client Solutions for the Industrial Engineering Team at Wipro.