- Digital champions from across the six sectors in India believe that being resilient, transparent and sustainable will prepare them for future growth

- Indian organisations are focusing on personalisation and customer-centric digital transformation solutions while global counterparts are inclined to innovation

- The payback period for technology deployments is lower for India as compared globally

- Companies in India that invested at least 3% of their entire sales in digital transformation had a higher proportion of high returns

New Delhi: The onset of industry 4.0 is leading the Indian manufacturing industry to a major transformation in terms of doing business operations. Shifting customer preferences, new distribution models, geopolitical uncertainties, supply chain disruption, and ESG regulations have given rise to new opportunities in terms of redesigning and innovating the existing business models. Various government initiatives like the production-linked incentive scheme (PLI) and ‘Make in India’ have contributed to the development of a favourable environment in the domestic market attracting global partnerships and foreign direct investments (FDI).

Given this context, PwC India recently conducted a survey to understand the current digital landscape in the Indian manufacturing industry and assess the prospect of laying down the future roadmap. CXOs of organisations in the domestic market, including multinational companies (MNCs), were interviewed to gain insights into the digital transformation trends of the manufacturing sector. Sharing insights from the survey titled Reimagining Digital Factories of Tomorrow, Sudipta Ghosh, Partner, Industrial Products Sector and Data and Analytics Practice Leader, PwC India, said

“This is a very interesting time for organisations, especially in India, who have embarked upon the digitisation journey. Organisations are focusing on improving the efficiency of processes, such as reducing the down time of assets, minimising the maintenance cost of expensive equipment, cutting down the cost of poor quality by understanding the parameters needed for the golden batch using digital twins, automation of processes like connected workstations using IoT for better visibility at the shop floor and workflow-based automated solution for efficient scheduling”.

Key trends emerging from the survey

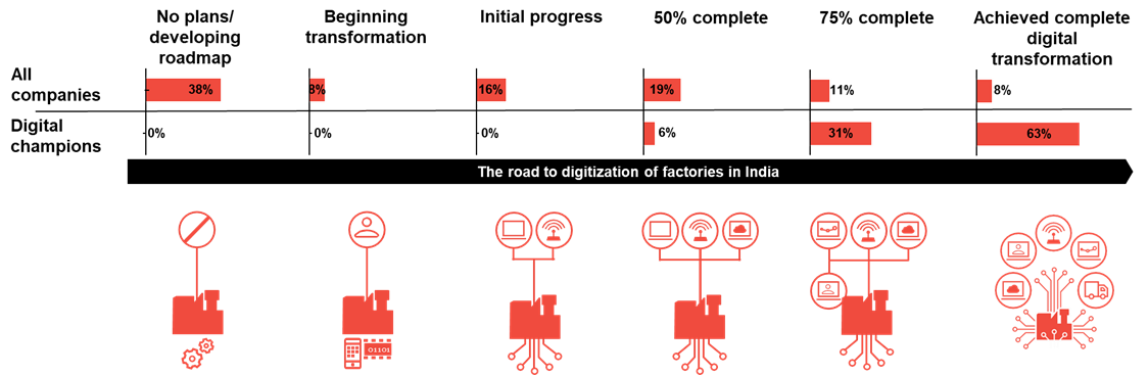

- 38% of the Indian companies that had participated in the survey revealed that they do not have any plans to adopt digital technology for their businesses. According to the research, digital champions from across the six sectors in India believe that being resilient, transparent and sustainable will prepare them for future growth. However, they also opine that greater innovation and faster time to market will help them to stay relevant in the competitive landscape in the coming days.

- Indian manufacturing companies currently prefer to adopt one standardised digital solution across plants compared to global companies which prefer one standardised digital solution with different functionalities or modules. Indian companies are showing an upward trend towards adopting analytics and AI with a current implementation rate of 54%.

- The average payback period is less than three years for the technology deployment use cases. Shorter payback periods encourage organisations to invest in technological solutions. Though investment in digital technology remains a challenge, lack of planning for aligning digital transformation with the organisation’s objectives and implementing digital technology remains a greater problem.

- Indian companies tend to focus more on people, policies and mindset while the global companies prefer to build up the right system for driving any transformation. Successful digital transformation demands elements of centralised standard-setting to establish best practices and guidelines, accompanied by centralised teamwork for local implementation.

The survey indicates that collaborating with the right team who can devise a custom digital transformation strategy which is suitable for the organisation, and working with the right enablers to implement the strategy is important to increase the return on investment (ROI).

“Organisations will also need to determine aspects of tangible returns apart from the financial outcomes to ensure that implementing digital technology has a holistic, long-term and sustainable impact on the business. Analytics continues to play a significant role in improving the decision-making process, both at the shop floor as well as across the entire supply chain. The return on investments will be governed to a large extent by how organisations are using the data to generate insights and take timely decisions.” Sudipta added

The road ahead

Though there is no single model for success, companies should frame a transformation blueprint having answers to key questions before committing to a digital transformation path. While learning from success stories within their industry may provide the insights on where to begin, it is important to take into consideration a wide variety of contingencies and probable pitfalls from failure case studies.Reiterating on the same, Ankur Basu, Partner and Digital Operations Leader, PwC India, said

“Though many companies have implemented fit-for-future technologies in some capacity to solve operational challenges, only few are able to implement it successfully across the value-chain. Adopting digital technologies effectively at scale requires the commitment of the leadership team besides a clear roadmap for implementation and skilled people.”

This survey has recommended key strategies for successful digital transformation of factories and outlined a strategic route focusing on people, process and technology.

- Digital strategy: Companies should be clear about their strategic targets and digital vision when it comes to the selection of use cases, business applications and technologies.

- IT architecture design: The architecture archetype, or digital backbone, is the key to achieving outcomes. The underlying IT architecture is both a solution and a risk area where companies can potentially lose the capability to implement digital solutions at speed and scale.

- Vendor strategy: Companies should consider whether they should devise their own digital solutions or buy it from external service providers.

- Agile platform, systems, use case and process development: During the development phase, the key question companies should consider is whether an agile delivery model is more suited to the organisation’s needs or whether they can implement the traditional waterfall model.

- Implementation and rollout: Digital rollouts can either be executed in a step-by-step manner or in a single rollout. However, the speed of simultaneous rollout carries its own risks, and companies should conduct a risk-benefit assessment before they implement it.

- Organisation, people and change: For a successful digital transformation strategy, organisations should consider the various nuanced aspects of their operations and then select the best-fit operating model tailored to their needs instead of copying peers.