Achieving accuracies thirty times greater than current industry standards, Estonian company GScan said it has set a new benchmark for non-invasive imaging of complex legacy structures.

Established in the 1960s, Paldiski was once home to the largest Soviet Union nuclear training centre, with two operational nuclear reactors installed in training submarines.

Before the Russian withdrawal in 1995, nuclear waste material was disposed of inside the submarine. As a containment measure, this waste and the reactors were encased in concrete as deep as 5m.

Control of the site was given back to Estonia, but the internal designs were classified as ‘State Secrets’. The situation is the same across Europe where multiple reactors, nuclear facilities, and nuclear waste deposits lack full documentation.

In a statement, Andi Hektor, GScan’s co-founder and chief strategy officer, said: “Muon flux scanning is now proven to offer a solution for mapping undocumented nuclear sites safely and accurately.

“The technology offers unparalleled accuracy, doesn’t require operators to spend long periods on site exposed to radiation, and can provide detailed information on both the structure and materials it contains.”

MORE FROM ENERGY & ENVIRONMENT

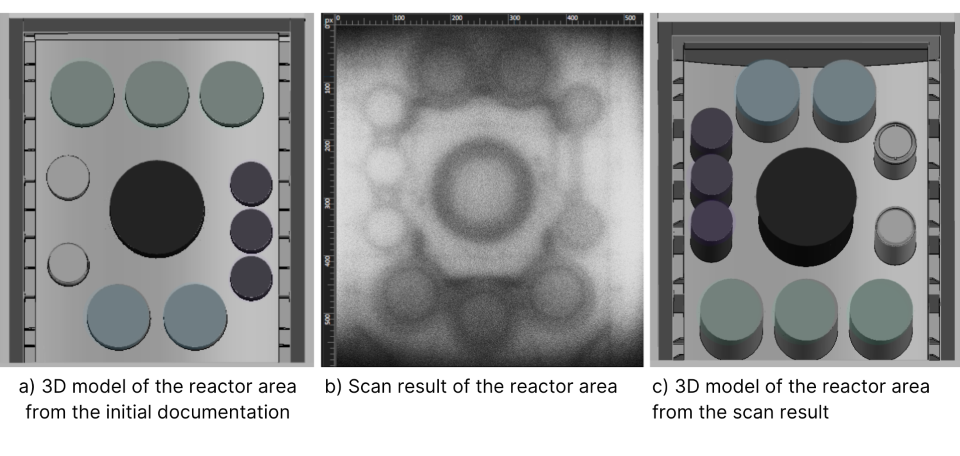

GScan uses muons, which are naturally occurring cosmic rays, to reveal items that may be hidden within tens of metres of a structure. Around 10,000 muons per square metre pass harmlessly through individuals, buildings and structures every minute, changing direction and speed based on the chemical composition of the objects they encounter. GScan’s scanners detect changes to the flow of muons (muon flux); it then uses AI to analyse this information, creating 3D models of the structure accurate to 1cm.

The Estonian Ministry of Environment required detailed plans of the reactors’ internal structure and the exact location of the nuclear waste material for safe dismantling and permanent disposal. Traditional imaging techniques such as ultrasound and ground penetrating radar are unable to scan steel or penetrate concrete beyond 1m. Consequently, they were unsuitable for the site where the reactors’ cylindrical sections measure about 14m in length and 9m in diameter.

Beyond nuclear, Muon flux scanning could also be applied in industries where traditional assessment methods fall short due to extreme conditions or access limitations. To this end, GScan is currently working on a maiden project with UK National Highways, assessing the integrity of steel components inside a post-tensioned concrete bridge.

“It can be used to optimise the ongoing maintenance of facilities in challenging or difficult-to-access environments, such as offshore rigs, infrastructure or metals manufacturing,” said Hektor. “Our method allows for a detailed and non-invasive analysis of almost any structure, helping to identify degradation and structural weaknesses before they become critical.”